Taizhou Xiongshi Plastic Mould Co., Ltd provide high quality plastic moulds, even for the daily life use plastic parts moulds. This case is a beer cup mould. Beer cup is hot sale in the summer, many people prefer to drink cool beer in the summer. This create huge quantity consume on the plastic bear cups.

In thus, beer cup mould have to be made with high quality. High quality mould can provide not only long mould life but also short cycle time. The cycle time is shorter, means higher profit. How to win the market and how to win the competitive is a question for study to make a high quality mould or normal quality mould.

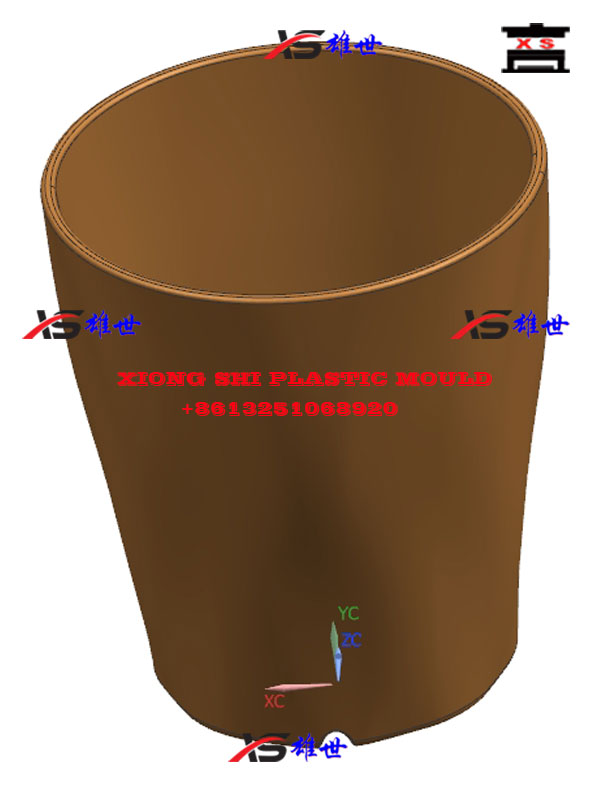

🎐 Cup design

Cup design provided by client. We just made the mould according client’s design. Of course, if draft angle or wall thickness have problem on the design, we will change it.

🎈 High quality cup mould steel

H13 steel for insert core and insert cavity. H13 steel after hardening treatment, its hardness upto 48-52HRC. Why we need to make core and cavity steel hardness so high? When steel hardenss is high, means not easy got wear and tear, then mould not easy got flash. Mould much longer life. However not all the mould fit for long life, especially for the mould which not require high production quantity, in this case mold made with long life high cost steel is just wast resources.

⛳ Long life mould design for the cup mould

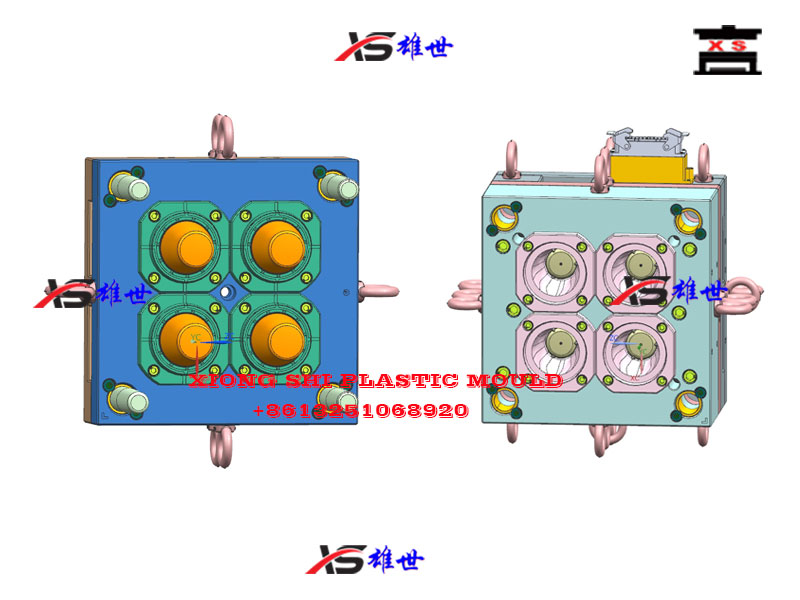

How to make a good or suitable mould design is not only the matter of the experience of plastic mould factory, but also the mould steel, mould price, product design, etc. Anyway, mould design is one of key factor for the mould production. As the following tooling job are all follow the mould design.

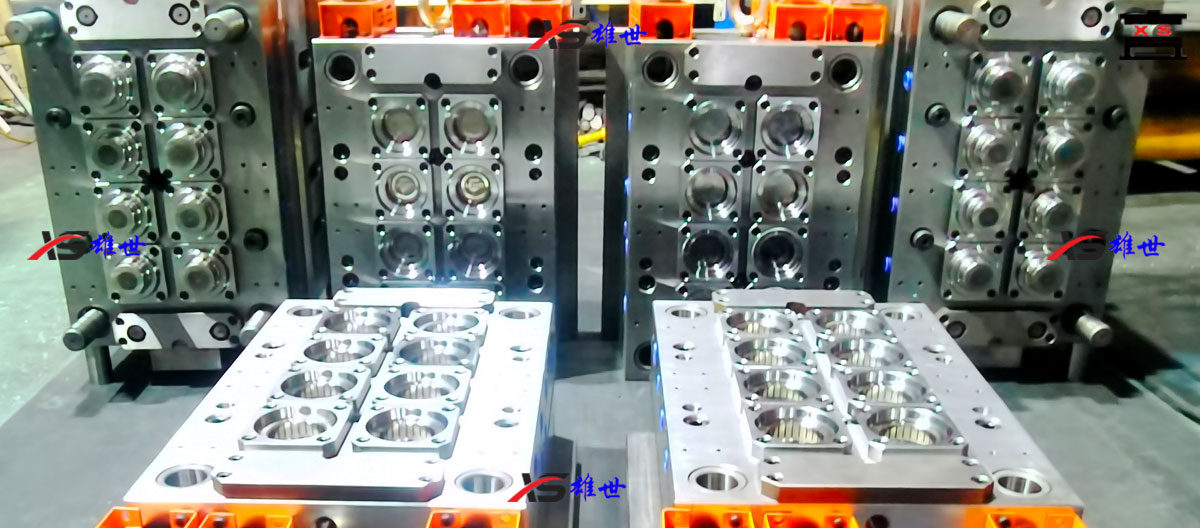

4 cavity individual self lock structure design, if have off centre problem on any one cavity of them, we can adjust them separately.

🎋 High quality cup mould tooling.

Tooling process not need special tooling, but need high precise tooling.

Core and cavity made with H13 steel, they needed vacuum quenching hardening treatment after rough tooling. This process make the difference happen between the normal hardness and high hardness mould steel, mould life is extended by 2-4times.

📌 High quality cup mould

Mould test is for checking the mould quality by mould injection moulding, if mould all the parts moving perfectly or not, if mould trail samples are good finish and sizes correct or not. This process provide us the opportunity to check the mould quality.

Transparent parts injection molding need good cooling. Need to make the mould running with a suitable temperature. So connect the mould with mould temperature controller is a good choose. The cooling system bear the key factor, good cooling system can make the mold temperature distribute evenly.

Our mould test injection machine testing more than 10 sets mould every day on the same injection machine. So the machine screw and barrel left with some different plastic material. In this case, it is difficult for us to produce very clear samples.